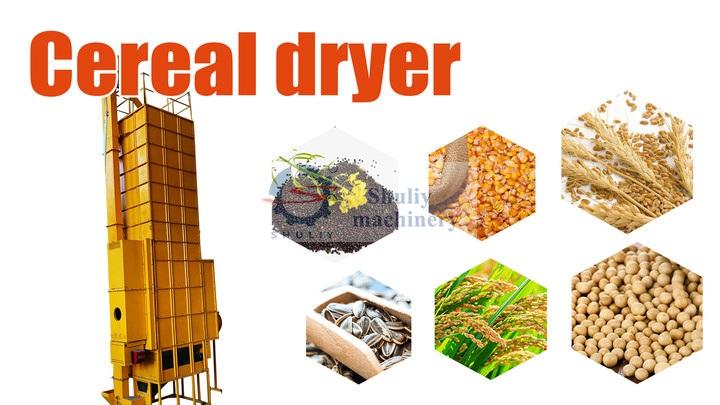

为什么选择我们的低温循环混流干燥机?

粮食干燥一般只持续十到二十天,属于连续工作,要求在使用过程中具有高稳定性和连续运行。这也对干燥机的材料应用和耐磨材料提出了更高的要求。

我们的粮食干燥塔采用低温、恒温,并利用清洁热源实现全覆盖、无死角干燥,确保粮食品质,无二次污染,性能稳定。低温干燥有助于更好地储存,对一些热敏性材料更友好。与横流干燥和逆流干燥相比,混流接触方式可以使物料达到更充分的干燥效果。干燥后的粮食内外一致,便于长时间储存。

混流粮食干燥机的优点

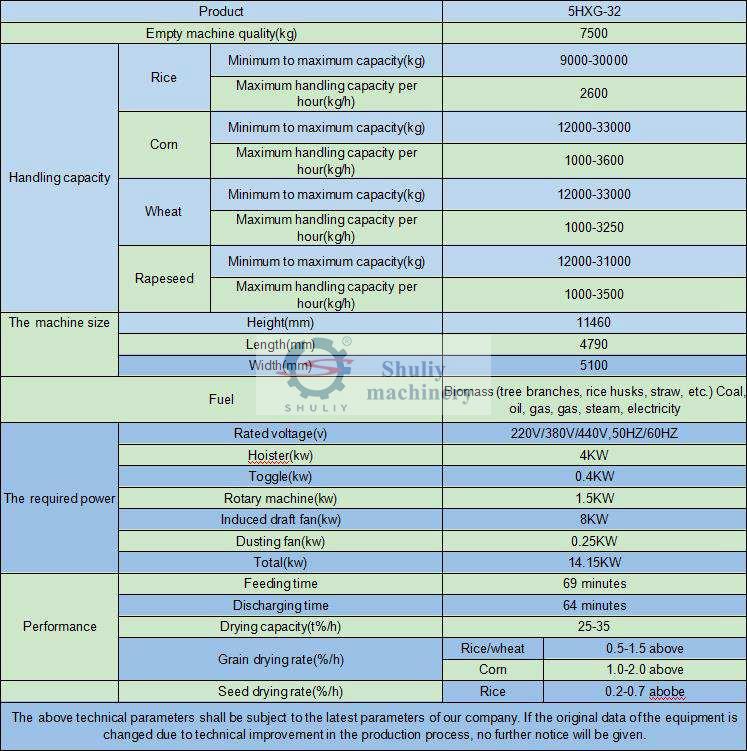

- 低功率应用: 粮食干燥塔的总功率(日产50吨)为7.6kW。可与普通农业用电并用,无需变压器,安装方便。

- 高干燥效率: 采用智能干燥技术,自动调节干燥温度和时间,以满足不同湿度粮食的需求。低温干燥使粮食受热均匀,爆裂率低,出芽率高。干燥后粮粒完整,确保粮食品质。

- 低热量、低能耗: 干燥器采用低温恒温,并使用换热气体的清洁能源进行充分覆盖与干燥,无死角、无二次污染。性能稳定,干燥水分在表层与内部一致,使粮食不发霉,便于长时间储存。

- 使用寿命长: 干燥器的主要部件为加厚板材与不锈钢导轨。干燥器的喷涂表面采用静电喷涂(寿命比普通喷涂高5倍以上)。

- 低干燥成本: 新型干燥器采用倾斜进风,具备通风顺畅、干燥均匀、全年无需清理的优点。