Why choose our low-temperature circulating mixed-flow dryer?

The grain drying generally only lasts ten to twenty days and it belongs to continuous work, which requires high stability and continuous operation during the using process. This also puts forward higher requirements for the dryer in the material application and wear-resistant material.

Our grain drying tower adopts low temperature, constant temperature and uses the clean heat source to realize full coverage and zero dead angles drying to ensure the quality of the grain, no secondary pollution, and stable performance. Low-temperature drying helps better storage and is more friendly to some heat-sensitive materials. Compared with cross-flow drying and counter-flow drying, the mixed-flow contact method can make the material achieve a more adequate drying effect. The dried grain is consistent inside and outside so that the grain is easy to be stored for a long time.

Advantages of the mixed flow grain dryer

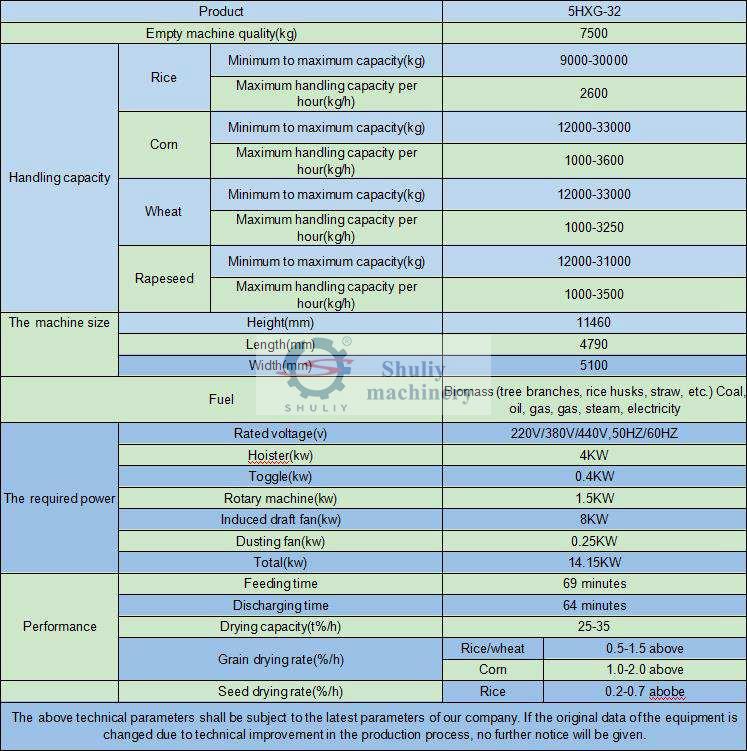

- Low application power: The total power of the grain drying tower (50 tons per day) is 7.6KW. It can be used with general agricultural electricity, no transformer is needed, and the installation is convenient.

- High drying efficiency: Intelligent drying technology is adopted to automatically adjust the drying temperature and time to meet the requirements of different humidity grains. Low-temperature drying makes the grain evenly heated, with a low burst rate and high germination rate. After drying, the grain particles are complete to ensure the quality of the grain.

- Low heat and energy consumption: The dryer adopts low temperature and constant temperature and uses the clean energy of heat exchange gas to fully cover and dry without dead ends, with no secondary pollution. The performance is stable, and the moisture of the drying is consistent between the surface and the inside, so that the grain will not be mildewed, easy to store for a long time.

- Long service life: The main components of the dryer are thickened plates and stainless steel runners. The paint surface of the dryer is painted by electrostatic spray paint (more than 5 times the life of general spray paint).

- Low drying cost: Our new type of dryer adopts angled air intake, has the advantages of smooth ventilation, even drying, and no need to clean up all year round.