Features at a Glance

Fruit Tray Making Machine is a pulp molding machine, which can extrude the pulp into various shapes and different sizes of fruit trays through the mold.

Fruit trays made by pulp fruit tray machine is a sustainable friendly packaging material, which is mainly used to protect and support fruits and other root vegetables during transportation and storage.

The capacity of Shuliy factory’s fruit tray making machine can be customized from 1000pcs/h to 7000pcs/h.

Production process of paper fruit tray making machine

- Raw material preparation: A suitable amount of pulp is selected as the raw material, which usually comes from recycled materials such as waste paper and cardboard.

- Pulp Preparation: Waste paper is shredded and mixed with water to make pulp by mixing and pulping.

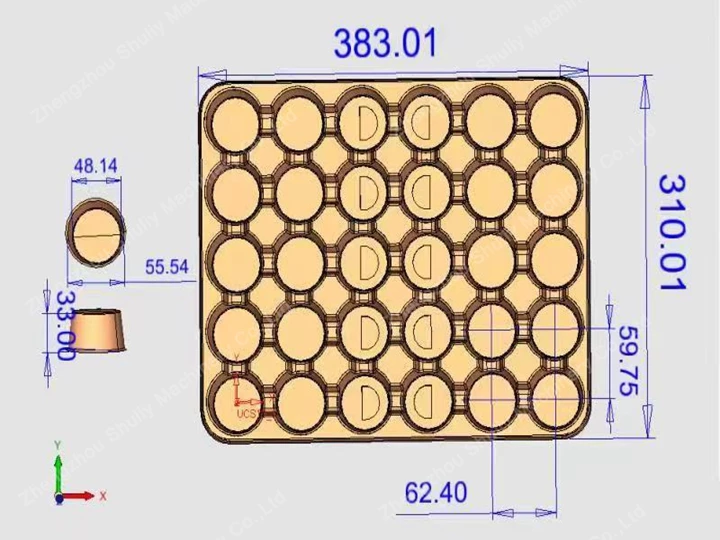

- Mold Design: According to the desired shape and size, design the corresponding mold.

- Molding: The fruit tray molding machine will automatically extract the appropriate amount of pulp, which will be adsorbed on the surface of the fruit tray mold and squeeze out the excess water through mechanical or vacuum action.

- Demolding and drying: The molded fruit trays are taken out of the molds and then run through drying equipment to remove the moisture and make them firm.

- Packaging: Finally, the fruit trays are inspected and packaged.

Why start the fruit trays business?

The equipment for the industrialized processing of fruit paper trays is now an important investment project for many investors. Among them, the paper apple tray making machine is an ideal machine for processing fruit trays.

This commercial apple tray processing machine can recycle various waste paper boxes and newspapers and process them into fruit trays of different specifications. Moreover, the size, color, weight, etc. of the processed paper apple tray can be customized according to customer needs.

Complete pulp fruit tray production line

The fruit tray production line is a fully automatic production line composed of a variety of machines. Its main machines include pulping machines, fruit tray making machines, dryers, and fruit tray packaging machines. This production line is mainly used for making paper fruit trays, the raw material is various waste paper.

Hot-sale fruit tray molding machine parameters

| Model | Capacity | Power | Voltage | Weight | Paper consumption | Water consumption | Size(molding machine) | Drying method |

| SL-2500-3X4 | 2500pcs/h | 55kw | 380V,50HZ | 4000kg | 200kg/h | 400kg/h | 2900*1800*1800mm | Brick kiln drying or multi-layer dryer |