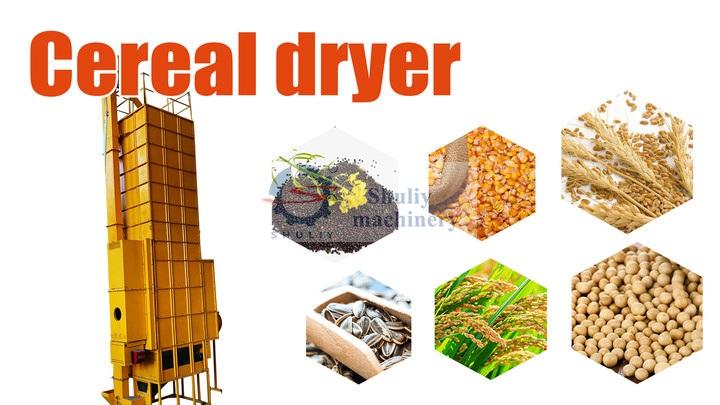

なぜ私たちの低温循環混合流乾燥機を選ぶのか?

穀物乾燥は一般的に10日から20日程度で、連続作業に属し、使用中は高い安定性と連続運転が求められます。これにより、乾燥機の材料適用と耐摩耗性に対してより高い要求が生じます。

私たちの穀物乾燥塔は低温、一定温度を採用し、クリーンな熱源を使用して、全面的なカバレッジと死角のない乾燥を実現し、穀物の品質を保証し、二次汚染を防ぎ、安定した性能を保ちます。低温乾燥はより良い保存に役立ち、熱に敏感な材料にも優しいです。横流乾燥や逆流乾燥と比べて、混合流接触方式は材料により十分な乾燥効果をもたらします。乾燥後の穀物は内外ともに均一で、長期保存が容易です。

混合流穀物乾燥機の利点

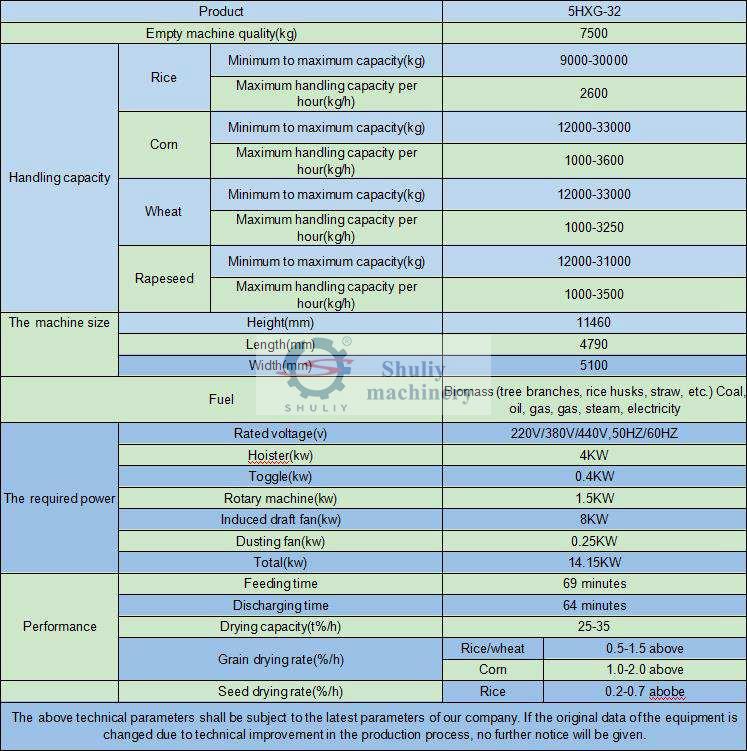

- 低い、適用電力: 穀物乾燥塔(1日50トン)の総電力は7.6kWです。一般的な農業用電力で使用でき、変圧器は不要で、設置が便利です。

- 高い乾燥効率: 智能乾燥技術を採用し、異なる湿度の穀物の要件を満たすように乾燥温度と時間を自動調整します。低温乾燥により穀物が均一に加熱され、破裂率が低く発芽率が高くなります。乾燥後は穀粒が完全で、穀物の品質を保証します。

- 低熱と省エネ: 乾燥機は低温・定温を採用し、熱交換ガスのクリーンエネルギーを使用して死角なく完全に覆って乾燥させ、二次汚染なし。性能は安定しており、乾燥後の表面と内部の水分が一致するため、穀物のカビが生えず、長期間の保存が容易です。

- 長い使用寿命: 乾燥機の主な構成は厚板とステンレス製ランナーです。乾燥機の塗装表面は静電塗装で塗装されており(一般的なスプレー塗装の寿命の5倍以上)。

- 低い乾燥コスト: 新型の乾燥機は角度のある吸気を採用し、換気が滑らかで均一な乾燥を実現し、年間を通じて清掃の必要がありません。