連続ナッツロースターは、材料のためにチェーンプレート輸送を採用し、自動温度制御の加熱システムと強力な熱風内部循環装置を備えています。これにより、高圧で制御可能な熱風が材料層に均一に浸透し、焼き効率と均一性を大幅に向上させます。

従来の設備と比較して、この機械は省エネ、環境に優しい、安定した性能、高速加熱、操作が簡単などの利点を持ち、食品業界の高品質で衛生的、国際標準の焼き要件を総合的に満たします。

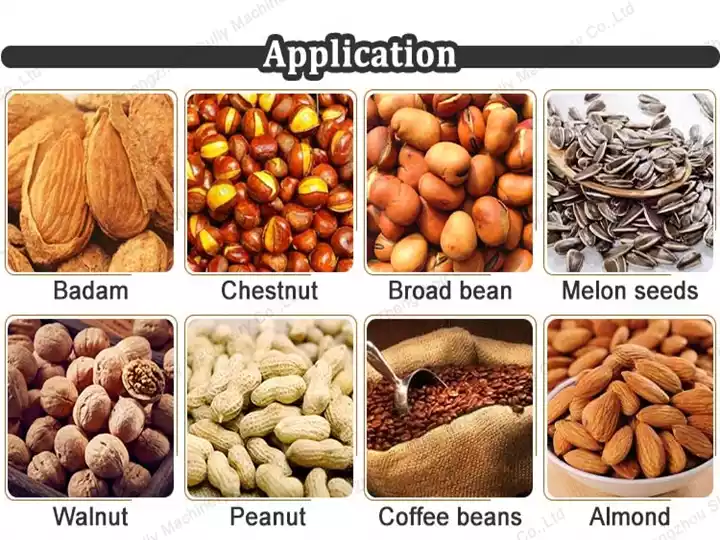

連続ナッツロースターの用途

この設備は、ナッツ、豆、農産物副産物の乾燥とローストに広く使用されています。その用途には:

- 落花生(殻付き/殻なし)、ゴマ、ひまわりの種、カボチャの種など、多様な油糧種子。

- 大豆、緑豆、エンドウ豆、そら豆などの豆類。

- カシューナッツ、アーモンド、クルミ、松の実、ヘーゼルナッツ、ピスタチオなどの高品質ナッツ。

- 乾燥唐辛子、乾燥果物、乾燥野菜、その他のフレーバーフード。

- 低温乾燥や高温焼きが必要な他の製品。

連続ピーナッツロースターの利点

- 高効率&省エネ:熱風循環と高品質断熱材を使用し、エネルギー消費と熱損失を大幅に削減します。

- 均一な焼き:高圧熱風が材料層に浸透し、均一な温度分布を確保し、一貫した色と本格的な食感を実現します。

- インテリジェントな温度制御:0-300°Cの範囲で柔軟に調整でき、多様なニーズに対応。低温乾燥から高温焼きまで対応可能。

- 高自動化:調整可能なコンベヤ速度と材料厚さにより、単一操作者で管理可能となり、労働コストを削減します。

- 安全性と衛生:すべての材料接触面は食品グレードのステンレス鋼で構築されており、食品安全と国際輸出基準を満たしています。

- 一体型冷却:後部に自動冷却システムを装備し、過焼きを防ぎ、製品の一貫性を向上させます。

- コンパクト設計と簡単なメンテナンス:合理的な全体構造により占有面積を最小化し、安定した運転と便利な操作・清掃を可能にします。

自動ナッツロースターのパラメータ

| 出力 | 加熱電力 | 伝送 電力 | 電圧 | 寸法 | 加熱 方法 |

| 約2000kg/h | 450kW | 32.5kW | 380V 50Hz 3相 | 約 15000*3250*2550mm | 電気加熱 |

連続ロースターの構造詳細

- リフティング装置:材料を自動的に供給入口に持ち上げ、手作業を削減し、人手を節約します。

- メッシュベルトシステム:さまざまな焼き材料に合わせた異なるメッシュベルトタイプを装備し、均一な広がりと輸送を保証します。

- 電気制御キャビネット:独立した温度制御システムを備え、調整可能な設定範囲は通常180-200°Cです。操作は簡単で、温度調整も正確です。

- 選別材料装置:材料が加熱コンベヤに入る前に一時的に保持し、連続かつ安定した焼きが可能です。

- 検査扉:焼き工程をリアルタイムで監視でき、運用の便宜と品質管理に役立ちます。

ピーナッツロースターの動作原理

- 給餌と輸送:操作員は材料を供給ホッパーに注ぎ、エレベーターによって自動的に焼きシステムに運ばれ、チェーンプレートに均一に分散されます。

- ゾーン加熱:焼き室には独立した上下の加熱要素があり、各ゾーンは個別に温度調整可能で、正確な制御を実現します。

- 高温焼き:高圧熱風が材料層に均一に浸透し、約20分で焼き上げ、色と食感の一貫性を確保します。

- 省エネルギー最適化:上下ゾーンのバーナーは補完的に動作します。個別のバーナーが故障しても、装置は正常に動作し続け、信頼性を確保します。

- 冷却工程:焼き後、材料は冷却ゾーンに入り、約10分以内に温度が下がり、過熱による湿気吸収による品質劣化を防ぎます。

- オプションの補助装置:入口側に振動給料装置を追加でき、出口側に振動収集装置を設置して生産効率と自動化レベルを向上させます。

効率的な連続ナッツロースターが必要な場合、ナッツ処理生産ラインにおいて、当社の設備は間違いなく信頼できる選択です。特別な要件があれば、お問い合わせください。