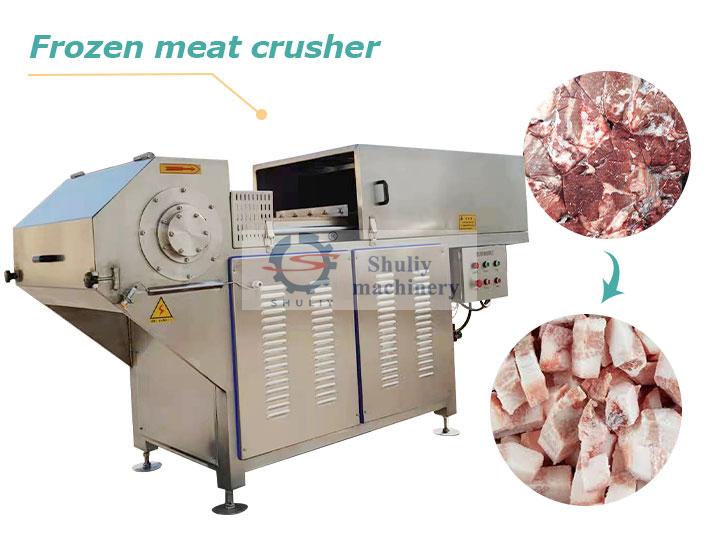

Frozen meat crusher has the advantages of being easy to use and operate, low noise, low vibration, reliable performance, and high production efficiency. The frozen meat cutting machine does not need to defrost when cutting frozen meat. So using the frozen meat crusher can reduce the user’s refrigeration cost in the production process. This frozen block crusher is all stainless steel. And its blade is made of alloy, with a sharp edge and reliable cutting. The frozen meat crusher’s cylinder is vertically backed and separated from the meat chute. And this design ensures that the frozen meat is not contaminated in any way.

Frozen block crusher features:

1、We can put the finished meat into the frozen meat grinder directly. So this improves the production efficiency.

2、Frozen meat crusher adopts reducer gear drive. So it cuts and feeds with reducer motor-driven gears. And works at the low noise, smoothness, and labor intensity.

3、Frozen meat crusher is 304 stainless steel. And it has a compact structure, easy to clean, and is in line with national health food requirements.

4、Frozen meat block crusher processing raw materials -18℃-0℃ frozen meat, can be directly broken into pieces, is the chopping machine and meat grinder before the process.

5、The use of this Frozen meat crusher can avoid pollution and nutrient loss caused by the slowing process. This not only ensures the freshness of meat but also eliminates the thawing process. So it greatly shortens the meat processing time and saves the cost.

6、The equipment has an external chute, so there will be no pollution of raw materials, and the exit can be equipped with a hoist to save labor.