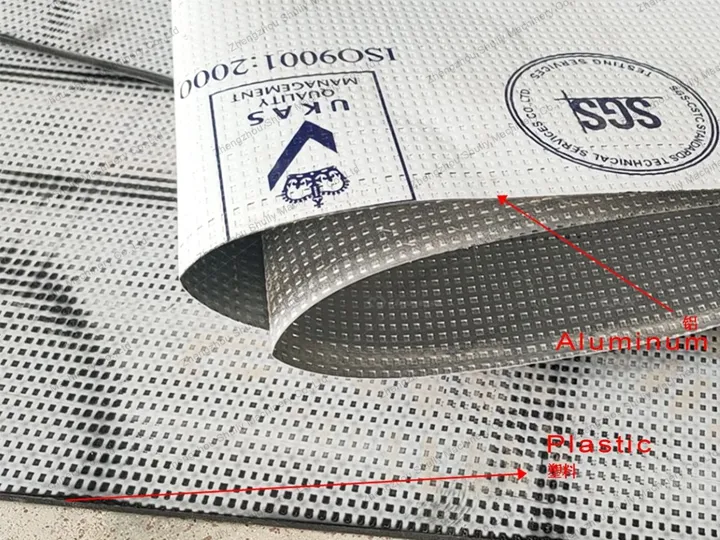

This ACP board heating separating machine is designed for recycling scrap aluminum composite panels (used in construction, decoration) by separating aluminum layers from plastic layers via dry physical heating—no water/pollution, 99% separation purity.

The ACP sheet separator machine can separate the aluminum-plastic composite material into aluminum and plastic. During the heating process of the machine, the aluminum plate and the plastic plate will be separated automatically. The structure of the machine is mainly the frame, separating device, feeding inlet, roller, discharge port, power, gearbox, electric control box, etc.

Main parameters of the aluminum plastic panel recycling machine

| Model | SL-600 separator | SL-800 separator | SL-1000 separator |

| Working width | 600mm | 800mm | 1000mm |

| Applicable | All kinds of ACP material | All kinds of ACP material | All kinds of ACP material |

| Size( L*W*H )(mm) | 1400*1500*1100 | 3900*2300*1100 | 3900*2500*1100 |

| Weight | 800kg | 1200kg | 1300kg |

| Voltage(customizable) | 380V/2.2KW,50HZ/3 phase | 380V/4KW,50HZ/3 phase | 380V/4KW,50HZ/3 phase |

| Capacity | 4t/8 hours | 4t/8 hours | 4t/8 hours |

| gas consumption | 2.5kg/h | 3.75kg/h | 4kg/h |

Note: the above are three of our factory’s best-selling models of scrap ACP stripping machines. We typically recommend suitable models based on customers’ raw material dimensions and processing capacity requirements. Machine voltage and plug types can be customized.

If you have questions about machine specifications or require customization, please feel free to contact us.

Waste aluminum composite panel separation equipment’s advantages

The ACP board heating separating machine is easy to operate, has no pollution, has low noise, and has high efficiency. Also, it is a dry physical separation. So, it does not cause secondary environmental pollution, with good social and economic benefits.

- The aluminum-plastic separator utilizes liquefied petroleum gas (LPG) heating, which is more energy-efficient than electric heating and results in a more affordable machine price.

- The machine features simple operation and high processing capacity. Once started, it requires only continuous feeding and discharging to maintain stable processing, capable of handling approximately 4 tons of aluminum-plastic waste every eight hours.

- The conveyor table length and width can be customized according to the customer’s actual application scenario.

What waste materials can be recycled by an aluminum-plastic panel separator?

Core Recyclable Materials (Building & Decoration Category)

- Used Finished Aluminum-Plastic Composite Panels: whole or fragmented panels salvaged from demolished exterior walls, curtain walls, interior ceilings, storefront signs, advertising display boards, etc.

- Production Scrap: strip, block, and fragment waste generated during cutting, slotting, and bending processes at aluminum-plastic panel factories (including laminated/coated panels).

- Construction Waste: scrap fragments, offcuts, and irregular pieces left over from on-site cutting and installation.

- Aluminum-Plastic Composite Panel Waste: scrap from composite panels, including aluminum-plastic honeycomb panels, aluminum-plastic insulation boards, and aluminum-plastic ceiling panels.

Common Processable Aluminum-Plastic Panel Types (by Material/Application)

- Standard exterior aluminum-plastic panels (PE core material, most common)

- Fire-resistant aluminum-plastic panels (flame-retardant core material)

- Fluorocarbon-coated aluminum-plastic panels

- Polyester-coated aluminum-plastic panels

- Mirror-finish / brushed aluminum-plastic panels

- Aluminum-plastic honeycomb panels (with aluminum honeycomb core)

- Aluminum-plastic insulation composite panels

Non-Recyclable / Difficult-to-Process Waste

- Severely contaminated waste containing large amounts of cement / mortar / adhesive

- Heavily carbonized or incineration-residue aluminum-plastic panels

- Mixed waste containing significant metal impurities, nails, or iron wire

- Non-aluminum-plastic composite panels (e.g., pure aluminum sheets, pure plastic sheets, aluminum honeycomb panels)

Why should we recycle aluminum-plastic composite panels?

With the increasing use of aluminum and plastic sheets in the market, the industry of processing and recycling aluminum and plastic sheets is slowly developing. Because we can reuse the stripped aluminum, it is conducive to resource conservation and environmental protection.

Aluminum holds high resource value

- Aluminum composite panels feature an aluminum surface layer (typically 0.1–0.5mm thick). Aluminum is a high-value recyclable metal.

- Aluminum is 100% recyclable

- Recycled aluminum requires only about 5% of the energy needed for primary aluminum production

- Market prices remain stable, offering substantial recycling profit margins

For recycling enterprises, aluminum represents a primary profit source.

Plastic Layer is Reusable

- The intermediate layer is predominantly PE plastic (polyethylene):

- Can be processed into recycled plastic pellets

- Can be used to manufacture plastic products or for fuel utilization

- Reduces landfill pressure from plastic waste

Both aluminum and plastic retain reprocessing value after separation.

Reduce construction and renovation waste pollution

Aluminum-plastic composite panels are widely used in:

- Building exteriors

- Retail store renovations

- Advertising signage

- Interior decoration

These materials are frequently replaced, generating substantial waste. Without recycling:

- They occupy landfill space

- Plastics resist natural degradation

- They cause resource waste

Recycling aluminum composite panels (ACP) offers significant economic value, environmental benefits, and advantages in resource reuse.

Contact us for the ACP sheet recycling solutions

We provide one-stop, turnkey recycling solutions for aluminum composite panel (ACP) / aluminum plastic board waste. With professional technical support, high-efficiency separation equipment and mature recycling processes, we help you turn waste ACP sheets into valuable recycled aluminum and plastic, realizing higher profit and environmental compliance.

Our advantages:

- Customized recycling solutions tailored to your material type, capacity, and site conditions

- High-purity separation with stable performance, easy operatio,n and low maintenance

- Full technical guidance: installation, training, production optimizatio,n and after-sales support

- Proven industrial experience in ACP recycling projects worldwide

- Eco-friendly, pollution-free physical recycling technology

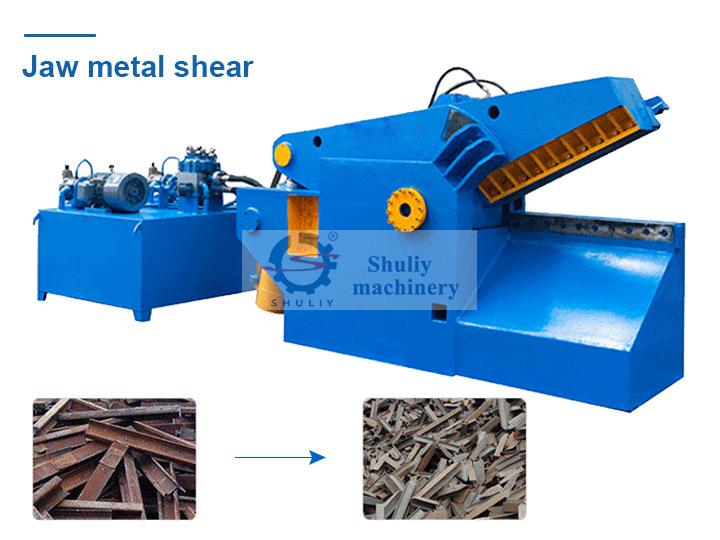

Whether you are a recycling station, manufacturer or recycling enterprise, we have the right solution for you. In addition, we also provide other metal recycling equipment, such as metal shredders, metal balers, rebar straightening machines, and a range of other metal recycling and processing equipment.

Contact us now for your professional ACP recycling plan and equipment quotation.