Dry ice blasting machines use the special properties of solid carbon dioxide (dry ice) to accelerate the spraying of dry ice particles onto the surface to be cleaned to remove dirt, grease, pollutants, and other impurities without leaving any residue.

Dry ice blasting machines also named dry ice cleaning machines or dry ice blasters, which is the most important equipment in the industrial cleaning field. The raw materials for cleaning by this machine are mainly dry ice pellets which are always made by the dry ice pellet machine. Therefore, the whole dry ice blasting system usually can be divided into two parts: dry ice pellet production and dry ice blasting.

Dry ice blaster parameters

Model: SL-HR-QX-40

Volume: 30kg

Adjustable dry ice dosage: 0-3kg/min

Air supply pressure range: 5-10bar

Compressed air flow requirement: 2-3m³/min

Power: 400W

Weight: 65kg

Dimensions (length×width×height): 60cm*40cm*70cm

Power supply: 220-240VAC, 1ph (50/60HZ), 3amps

How dry ice blaster machine work?

- Dry Ice Pellet Production: The first step in dry ice cleaning is the formation of solid dry ice pellets by spraying liquid carbon dioxide (CO2) through a dry ice pellet machine and depressurizing it during the spraying process, causing it to expand and cool rapidly.

- High-Speed Blasting: The generated dry ice pellets are accelerated by a high-speed blower or compressed air and blasted onto the surface to be cleaned. These dry ice particles have a high velocity during the blasting process and generate kinetic energy.

- Heat-cooling Exchange: The dry ice particles in contact with the surface, due to their extremely low temperature (approx. -78.5 degrees Celsius), rapidly transfer their low-temperature energy to the dirt surface.

- Thermal Shock: Surface dirt experiences a thermal shock effect due to the sudden temperature change, causing the dirt to rapidly solidify, shrink, and crack.

- Physical Impact and Vaporization: The high-speed impact, cooling effect, and instantaneous expansion of the dry ice pellets cause dirt to be dislodged from the surface, and in some cases, the dirt is removed directly by the vaporization of the dry ice pellets.

- No Residue: Dry ice particles are a direct transition from solid to gas during the cleaning process, leaving no moisture or other residue, making dry ice cleaning a clean, residue-free cleaning method.

Main uses of dry ice blasting machines

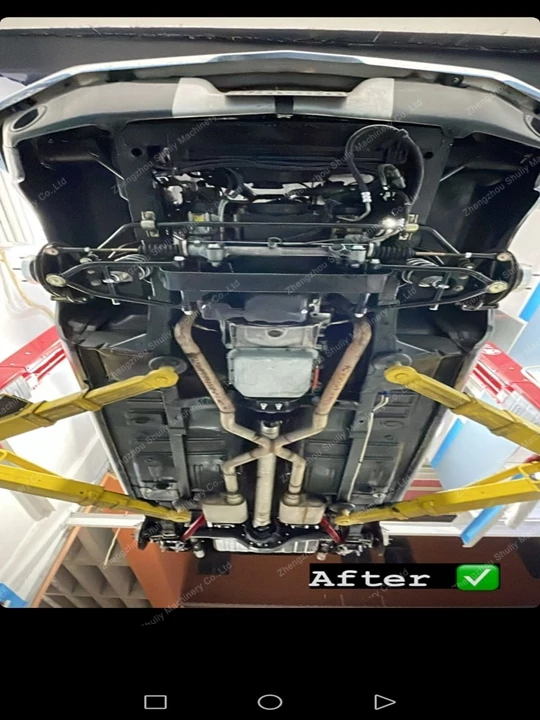

Dry ice blasting machines are widely used, especially in the industrial manufacturing industry and the automotive cleaning industry.

Most of our customers purchase this machine for car cleaning centers. Dry ice car cleaning mainly includes engine cleaning, wheel hub and brake system cleaning, car interior and parts cleaning, car tire cleaning, etc.

In addition, dry ice cleaning has a wide range of uses in other areas.

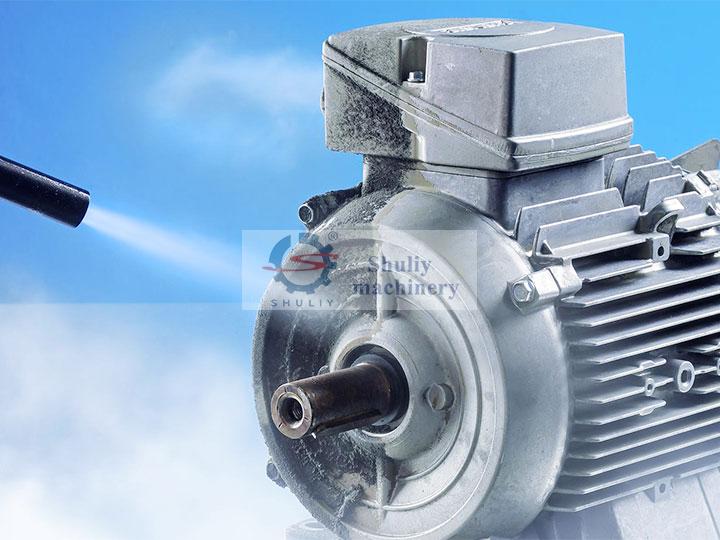

- Industrial cleaning: Dry ice cleaning machines can be used to clean various industrial equipment, mechanical parts, and production lines. It effectively removes grease, coating, dirt, and more without leaving behind moisture.

- Food production equipment cleaning: In the field of food and beverage production, dry ice cleaning can be used to clean production equipment, conveyor belts, ovens, etc. to ensure a hygienic food production environment.

- Electronic equipment cleaning: Dry ice blasting machines have advantages for cleaning electronic equipment, circuit boards, and precision instruments. Because dry ice cleaning does not require moisture, it will not cause damage to electrical appliances.

- Construction and Paint Cleaning: Dry ice blasting is highly effective at removing paint, coatings, and dirt from construction surfaces without the use of chemical solvents.

- Medical equipment cleaning: In the medical industry, dry ice cleaning machines can be used to clean medical equipment, surgical instruments, etc. to ensure a high degree of cleanliness of the equipment.

- Aerospace equipment cleaning: Used to clean the surfaces of aircraft parts, spacecraft components, and aerospace equipment to ensure their performance and safety.

- Mold and industrial equipment maintenance: In manufacturing, especially in the maintenance of molds and industrial equipment, dry ice cleaning can effectively remove residues on the mold surface.

- Cold chain equipment cleaning: Dry ice cleaning can be used to clean the internal and external surfaces of refrigeration and freezing equipment to ensure the hygiene and efficient operation of the equipment.

Dry ice blasting machine working features

The role of a dry ice pellet machine is to make liquid carbon dioxide into a certain specification of dry ice particles or dry ice cubes. The dry ice blasting and cleaning machine adopts the special configuration of the air compressor to make the compressed air.

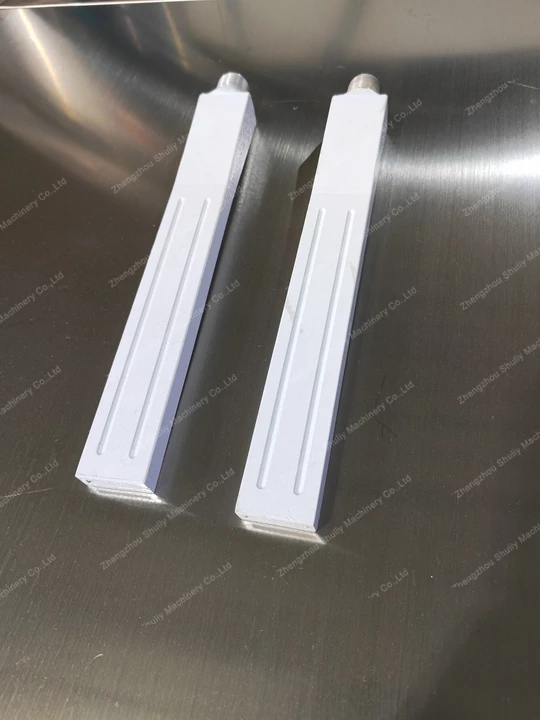

Put the dry ice pellets(3mm is best) into the dry ice blasting machine, under the driving of compressed air, high-density dry ice particles or fine dry ice powder will be sprayed with compressed air to the surface of the object to be cleaned, to play a role in cleaning.

Related equipment recommendations

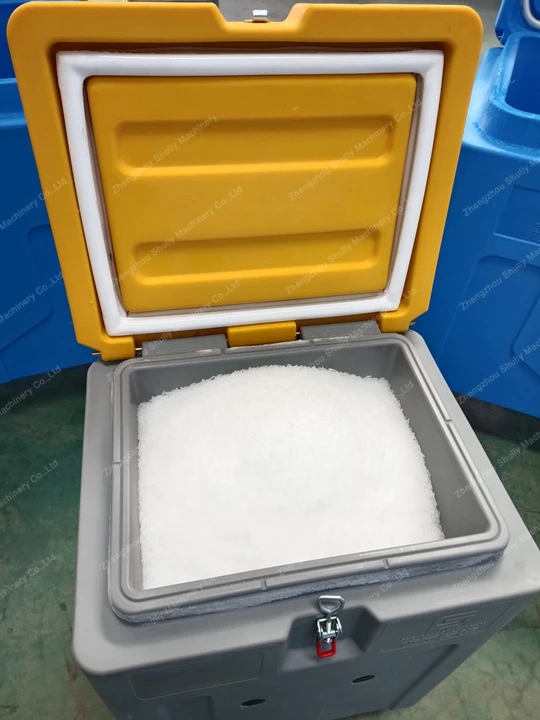

When using a dry ice blaster, it is important to ensure that there is an adequate supply of the raw material, i.e. dry ice pellets, to ensure that the machine continues to work.

The most common sizes of dry ice pellets used for dry ice cleaning are 3mm or 6mm in diameter, and for stand-alone processing of the required dry ice pellets, our plant can also supply a high-quality dry ice pelletizer.

In addition, we offer a wide range of dry ice storage boxes with different volumes for efficient storage of dry ice pellets.