The commercial Jacketed Cooking Kettle is a practical cooking tool commonly used in medium to large restaurants and food processing plants. It can be used to process all kinds of dishes, including porridge and rice, sauces, boiling sugar and chocolate, and frying all kinds of nuts. The volume of the jacketed cooking kettle varies from model to model, commonly 100L, 200L, 300L, 400L, 500L, and even larger.

Working principle of the jacketed cooking pot

- Sandwich design: The bottom of the jacketed cooking kettle is designed with a sandwich, which is filled with thermally conductive materials, such as aluminum alloy, copper, etc. The interlayer design helps distribute heat evenly and improves heating efficiency.

- Heat source conduction: When the jacketed pot is placed on the stove, the heat generated by the stove is first transferred to the heat-conducting material in the interlayer. These thermally conductive materials have good thermal conductivity and can quickly transfer heat to the surface of the pot.

- Heat distribution: After the heat is transferred from the interlayer to the surface of the pot, it will spread along the bottom and sides of the pot. Since the bottom and sides of the pot have a larger area in contact with the food, the heat can be evenly distributed to all parts of the food.

- Cooking effect: The working principle of the jacketed cooking kettle is mainly to achieve the cooking effect by isolating the heat source and ingredients. The internal structure consists of two pots of different sizes separated by a layer of air. This layer of air can isolate the heat source and the ingredients, making the ingredients evenly heated and less likely to burn.

- Nutrient retention: Since the cooking method of the jacketed cooking pot uses an air layer that isolates the heat source and the ingredients, the nutrients of the ingredients will not be lost due to high temperature. At the same time, the cooking method of the sandwich pot can also retain the taste of the ingredients, making the ingredients more tender and delicious.

Three types of heating methods for jacketed cooking kettle

The jacketed cooking kettle has three heating methods: electric heating, gas heating, and steam heating. Customers can learn about the characteristics of different heating methods through the following content, and choose a jacketed pot that suits them according to their needs.

- The steam-jacketed kettle uses the steam generated by the boiler to pass into the jacketed kettle for heating.

- The electric heating jacketed kettle is heated by heating the thermal oil through the electric heating tube.

- The gas-heating jacketed kettle is mainly composed of a pot body, a base, a burning appliance, and a pot tilting device. When working, you must first open the gas valve and ignite the gas to heat the pot.

Parameters of jacketed cooking kettle

| Model | TZ-50 | TZ-100 | TZ-200 | TZ-300 | TZ-400 | TZ-500 |

| Size(mm) | 750*750*700 | 850*850*750 | 950*950*800 | 1050*1050*850 | 1150*1150*900 | 1250*1250*950 |

| Power | 0.75kw | 1.1kw | 1.1kw | 1.5kw | 1.5kw | 2.2kw |

| Capacity | 50L | 100L | 200L | 300L | 400L | 500 L |

| Weight | 60kg | 90Kkg | 120kg | 150kg | 180kg | 220 kg |

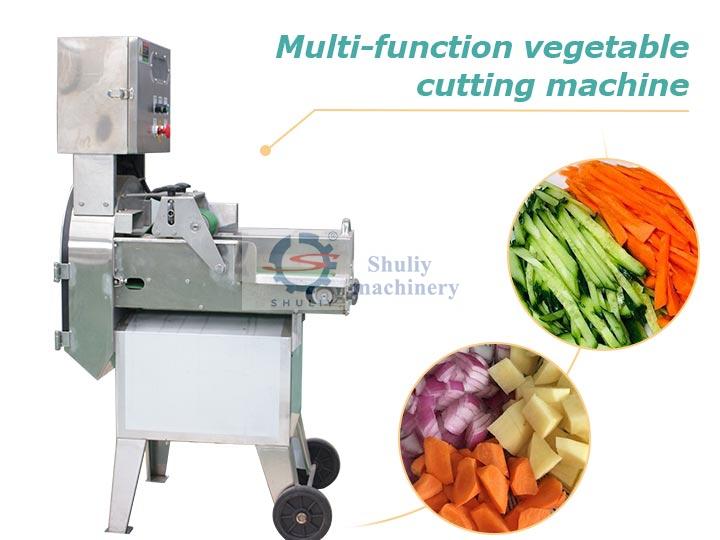

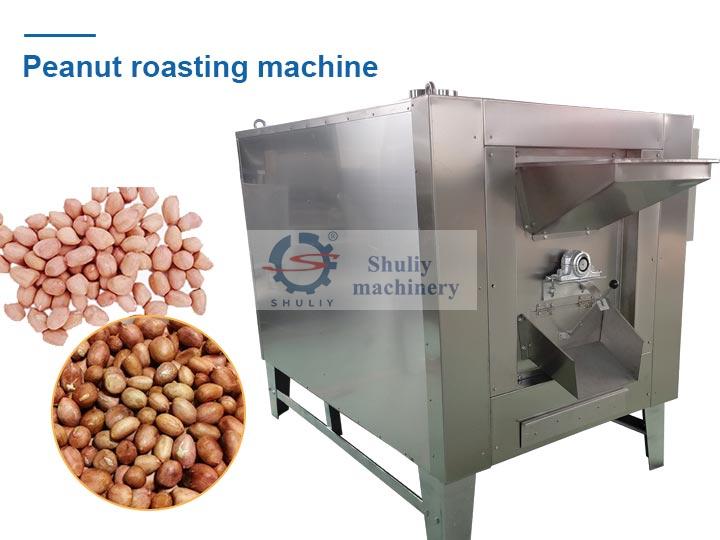

Shuliy factory, as a professional food processing equipment supplier, can supply not only different types of sandwich cookers but also other kinds of related food processing equipment, such as fruit and vegetable washing machines, vegetable cutters, deep fryers, packing machines, and so on. Please feel free to ask us for quotations.